NX Flow

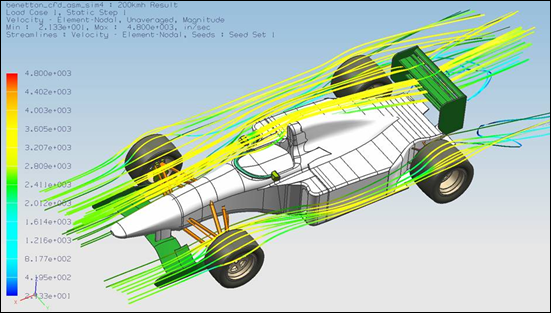

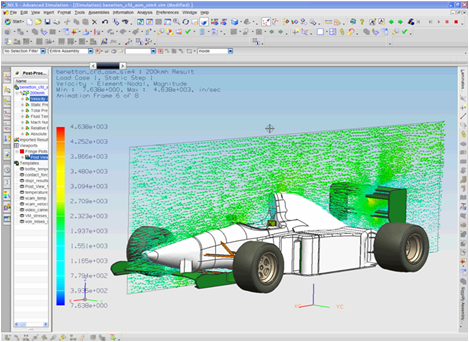

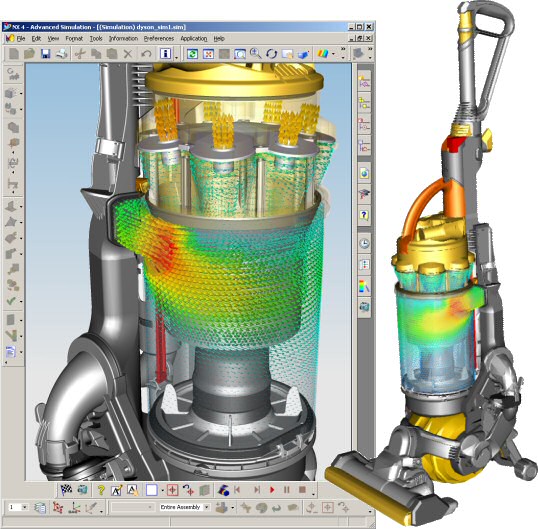

NX™ Flow es el módulo de análisis de fluidos (CFD) integrado en el entorno NX Advanced Simulation. Ofrece herramientas sofisticadas de análisis de fluidos y transferencia de calor de piezas y ensamblajes complejos. NX Flow permite realizar de forma rápida y exacta simulaciones de análisis de fluidos para conocer el comportamiento del producto en la fase de diseño y desarrollo de producto solution para reducir costes y acelerar el lanzamiento del producto al mercado al reducir el número de prototipos y ensayos físicos. NX Flow se aplica en un amplio rango de industrias, incluyendo: espacio y defensa, automoción, productos de consumo, componentes electrónicos de alta tecnología, medicina, procesos y generación de potencia.

FEMAP TMG Thermal incluye capacidades de simulación térmicas para resolver problemas en régimen permanente y/o transitorio con conducción, convección, radiación y cambios de fase, así como una potente herramienta para manejar ensamblajes llamada Thermal Coupling que permite acoplar flujos de calor entre piezas de un ensamblaje.

Los modelos de geometría compleja con mallado desestructurado ofrecen la máxima flexibilidad. Permiten emplear cualquier combinación de elementos 3-D, 2-D y 1-D soportando cualquier mallado y tamaño de elemento, incluso elementos axisimétricos. Las propiedades de materiales sólidos pueden ser isotrópicas o anisotrópicas, y pueden variar con la temperatura y otras condiciones. Las propiedades de los fluidos pueden variar con la presión y la temperatura. La conduction se modeliza mediante términos de conductancia lineales calculados mediante el método de volúmenes de control que usa una función de temperatura en el elemento restringida a los puntos de cálculo en el contorno y en el centro geométrico. También se ofrece el método del centro del elemento basado en las leyes de Fourier con reducción lineal.

NX Flow solves practical engineering challenges such as

- Computing:

- Fluid pressure and velocity fields within and around complex geometries (both internal and external fluid flow simulations).

- Investigating:

- Start-up, shut-down or system failure transient performance degradation conditions.

- Forced and natural convection cooling schemes.

- Spacing requirements between parts.

- Optimizing:

- Placement of critical components.

- Size and shape of heat sinks.

- Position and sizing of fans, inlets, vents, and outlets.

- Determinining:

- Size of wing profiles or critical car component shapes.

- Drag, lift, or other forces and pressures acting on complex surfaces.

- Head loss across a system or subsytem.

- Operating point of a cooling fan.

- Designing:

- Air and thermal comfort systems (HVAC cabin design).

- The best fluid pipe pattern throughout a complex hydraulic system assembly.

In essence, NX Flow allows engineers to solve very complex systems numerically. It describes and predicts the flow of air, gases, or other fluids and liquids around or through any engineering product assembly. Analyzing the flow patterns and pressure regulation of fluid within an automative transmission cooling system or the flow of air within an HVAC system for cabin thermal comfort are two typical examples of NX Flow applications.

NX Flow can be used in tandem with the NX Thermal product for seamless modeling of explicitly coupled forced and natural convection problems, including radiation heat transfer.

NX Flow solver capabilities

- FE-based finite volume CFD scheme

- Navier-Stokes equations for both steady state and transient flow

- Internal or external flows

- Turbulent, laminar and mixed flows

- Multiple 1st and 2nd order advection with or without flux limiters

- Efficient time stepping and other algorithms for fast transient calculations

- Unstructured fluid meshes (supports any combination of tetrahedral, brick, pyramid, and wedge elements: linear and parabolic types)

- Fluid buoyancy terms

- Automatic connection between disjoint fluid meshes

- CFD intermediate results recovery allowing solver restart

- Forced, natural and mixed convections

- Multiple fluids in separate enclosures

NX Flow modeling capabilities

-

Automatic skin mesh (boundary layer mesh) with unlimited layer options

-

Complete set of automatic and/or manual meshing options for the selected fluid domains

-

Heat loads and temperature restraints on the fluid domain

-

Multiple enclosure definitions

-

Embedded 2D/3D flow blockages

-

Losses in fluid flow due to screens, filters and other fluid obstructions

-

Porous media modeling (including orthotropic porous blockages)

-

Head loss inlets and openings (fixed or proportional to calculated velocity or squared velocity)

-

Fluid swirl and turbulence criteria at inlet and internal fans

-

Fluid recirculation loop with head loss or heat input/loss or fluid temperature change between unconnected fluid regions

-

Nonlinear flow boundary conditions

-

Altitude effects

-

Nonlinear fluid properties

NX Flow modeling capabilities

-

Conduction, convection and radiation conjugate heat transfer solver

-

Nonlinear thermal contacts

-

Thermal couplings (welded, bolted, bonded, or thermal contact connections) for assembly modeling

-

Disjoint thermal/fluid meshes support in assembly modeling

-

Surface-to-surface, edge-to-surface radiative heat transfer

-

Thermal solution customization (user subroutine)

-

Hemicube-based view factor calculation (using graphics’ card hardware)

-

Thermal model substructuring for radiation heat transfer view factor calculations

-

Radiation in participating media

-

Radiation enclosures

-

Radiative sources

-

Diurnal solar environmental heating (including cloud, altitude, longitude and latitude, and pollution effects)

-

Specular and transmissive surfaces

-

Optical radiative ray tracing

-

Forced and natural convection correlations

-

Hydraulic fluid networks

-

Joule heating

-

Phase change and thermal ablation

-

Heater and thermostat modeling

-

Peltier cooler modeling

-

Open architecture solution customization (user subroutines)

Results post-processing options

-

Fluid velocity (arrow plots and/or streamlines)

-

Pressure

-

Fluid density

-

Mass flux

-

Temperature

-

Total thermal load/flux

-

Convective heat flux

-

Convective coefficient

-

Volume/mass flow rate

-

Shear stress

-

Pressure on solid faces

-

Fluid shear forces (viscous forces) on solid faces

-

Drag/lift acting on objects

-

Conductive heat flux

-

View factor sums

-

Radiative heat flux