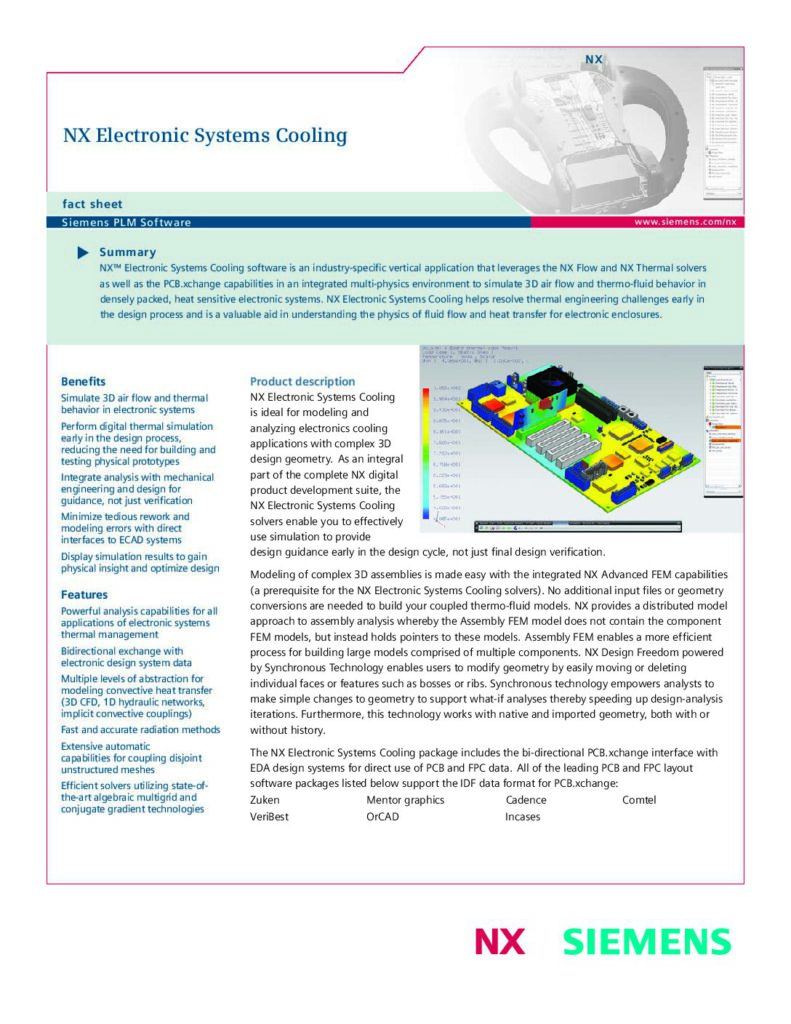

NX Electronic Systems Cooling™

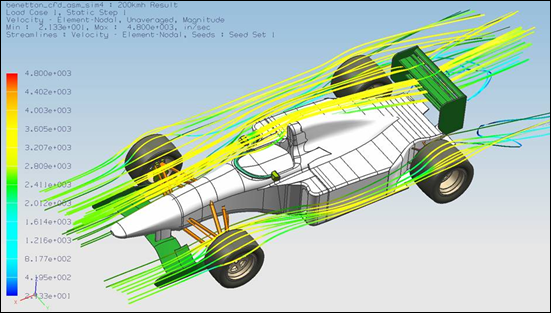

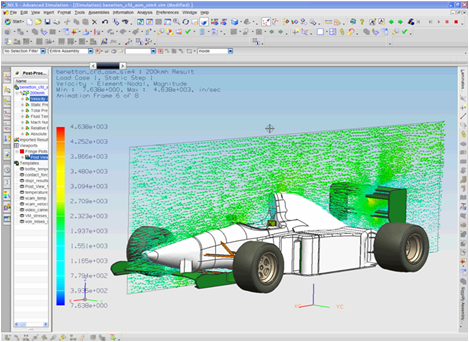

NX TMG Electronic Systems Cooling for NX Advanced Simulation environment is an industry-specific vertical application that leverages the NX Flow and NX Thermal solvers as well as the PCB.xchange and other high tech and electronics industry-specific cooling capabilities in a bundle product. It provides a comprehensive set of tools to simulate 3D air flow and thermo-fluid behaviour in high tech and electronic systems.

NX Electronic Systems Cooling helps resolve thermal engineering challenges early in the design process and is a valuable aid in understanding the physics of fluid flow and heat transfer for electronic enclosures and cooling applications.

Some practical applications

- Determining electronic systems cooling strategies

- Enclosure, subsystem and power supply thermal management

- Detailed thermal design of PC boards and multi-chip modules

- Thermally sensitive and critical components placement

- Heat sinks modeling

- Spacing requirements between critical parts

- Predicting fan operating conditions

- Volume and mass flow estimations

- Computing pressure inlet/outlet gradients and head losses

- Identifying recirculation areas and hot spot issues

- NX Electronic Systems Cooling has an interface with EDA design systems for direct and bi-directional PCB and FPC data exchanges. All of the leading PCB and FPC layout software packages are supported:

- Zuken

- Mentor Graphics

- Cadence

- VeriBest

- OrCAD

- Incases

- Comtel

Main NX Electronic System Cooling features

- Specific capabilities for electronics simulation applications

- Heat sink models library and heat sink modeler

- Electronic thermal component library

- Fan catalogue (database of fan curves) with more than 2000 fans from leading manufacturers

- PCB modeler/xchange (ECAD/MCAD bi-directional data exchange)

- NX Electronic Systems Cooling general simulation capabilities

- Steady-state and transient analysis (adaptive correction multigrid solver)

- Turbulent (k-εe, mixing length), laminar and mixed flows

- Internal or external flows

- Automatic skin mesh (boundary layer mesh) with unlimited layer options

- Complete set of automatic and/or manual meshing options for the selected fluid domains

- Unstructured fluid meshes (supports any combination of tetrahedral, brick, pyramid and wedge elements-linear and parbolic types)

- Multiple 1st and 2nd order advection with or without flux limiters

- Efficient time stepping and other algorithms for fast transient calculations

- Solution intermediate results recovery allowing solver restart

- Heat loads and temperature restraints on the fluid domain

- Forced, natural and mixed convection

- Fluid buoyancy

- Multiple enclosures

- Multiple fluids

- Losses in fluid flow due to screens, filters and other fluid obstructions (including orthotropic porous blockages)

- Head loss inlets and openings (fixed or proportional to calculated velocity or squared velocity)

- Fluid swirl at inlet and internal fans

- Fluid recirculation loop with head loss, heat loss, heat input/loss or fluid temperature change between unconnected fluid regions

- Automatic connection between disjoint fluid meshes

- Altitude effects

- Nonlinear flow boundary conditions

- Nonlinear thermal contacts

- Thermal couplings (welded, bolted, bonded, and other thermal contacts) for assembly modeling

- Disjoint thermal/fluid meshes support in assembly modeling

- Surface-to-surface radiative heat transfer

- Thermal solution customization (user subroutine)

- Hemicube-based view factor calculation (using graphics card hardware)

- Radiation enclosures

- Radiative sources

- Diurnal solar environmental heating (including cloud, altitude, longitude and latitude effects, pollution and other solar attenuation effects)

- Specular and transmissive surfaces

- Hydraulic fluid networks

- Joule heating

- Heater and thermostat modeling

- Peltier cooler modeling